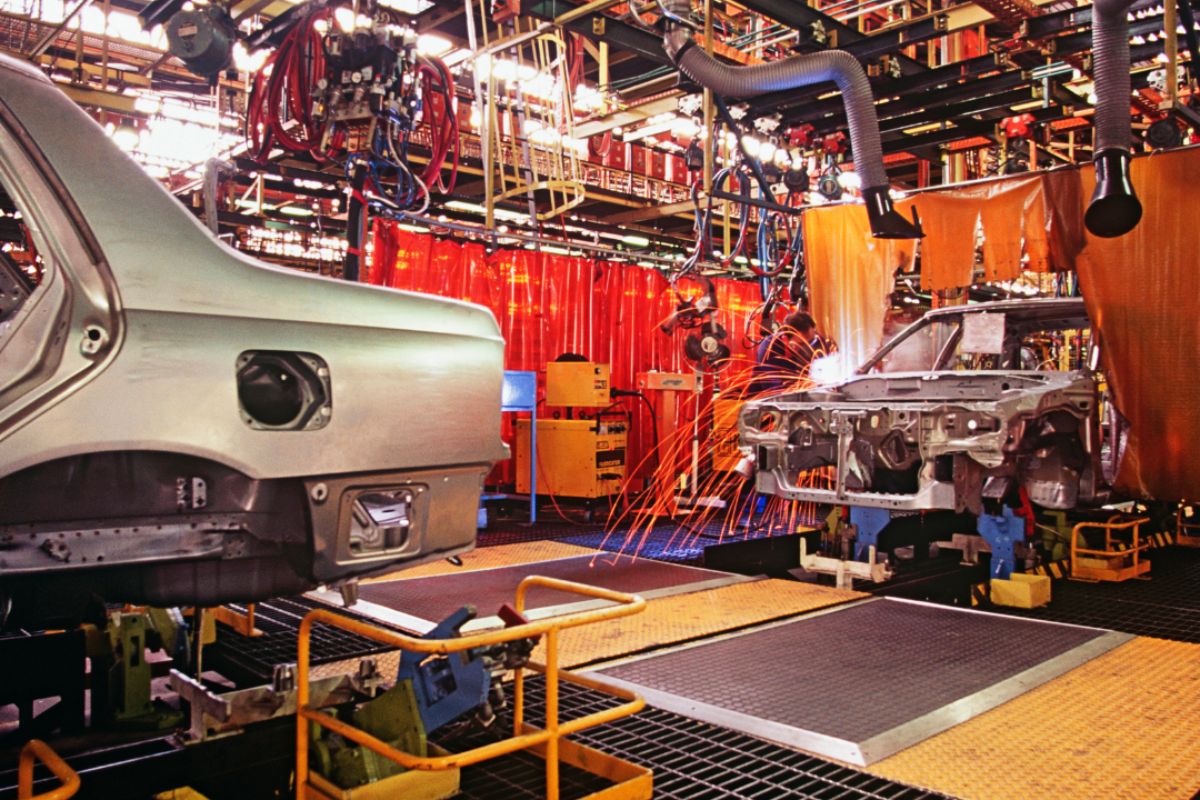

Empowering Manufacturing and Process Operations

Whether they are creating goods or processing raw materials, Industrial complexes represent the core of production in the manufacturing and process sectors. These facilities demand a substantial amount of power to operate various pieces of equipment, machinery, and systems. Managing the electrical infrastructure within these industrial sites can be challenging as they require a comprehensive and efficient power distribution network that includes both high voltage (HV) and low voltage (LV) systems and equipment.

Engineering Power Solutions (EPS) play a crucial role in tailoring electrical assets to the specific requirements of manufacturing and process facilities. Leveraging our wide-ranging expertise and cutting-edge technologies such as ETAP, DIgSILENT, and CDEGs we can identify and design the most appropriate electrical power distribution structure for your facilities, specify the correct equipment, and seamlessly integrate electrical controls. The outcome is a bespoke, future-proof electrical infrastructure that efficiently supports your operations.