Background

Client: Undisclosed

Industry: Renewables

Location: Scotland, UK

Date: May 2025

Project Overview

A major UK-based energy facility (operational for over a decade) required a detailed earthing condition assessment of its HV and LV earthing infrastructure. The site includes numerous transformers, interconnected high-voltage switchrooms, and a combined HV/LV earthing electrode system.

Given the safety-critical nature of their facility, EPS was engaged in verifying operational safety and compliance with regulatory standards.

Objectives

Our assessment included a structured program of on-site tests carried out over 5 days. Through these inspections, we aimed to:

- Verify the condition and continuity of earth bonds site-wide, structural metalwork, and associated electrical equipment.

- Assess soil resistivity to support wider system earthing modelling & design studies – including step & touch voltage and earth potential rise (EPR).

- Measure overall earth resistance across the facility and test the effectiveness of perimeter bonding.

- Confirm compliance with BS EN 50522 and BS 7430 guidelines for earthing in electrical installations.

Scope of Work

| Task | Overview |

|---|---|

| Visual Inspections | Identification of any damaged or missing bonds, corrosion, or incorrect terminations |

| Continuity Testing | Assessing the electrical measurements between key earthing points, i.e. switchgear, transformers, cable trays, and perimeter fencing. |

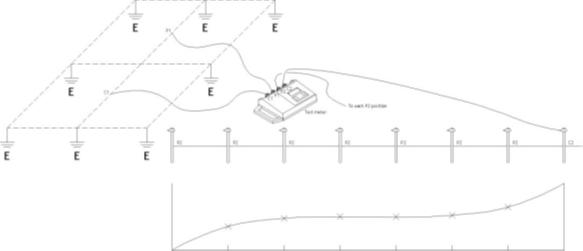

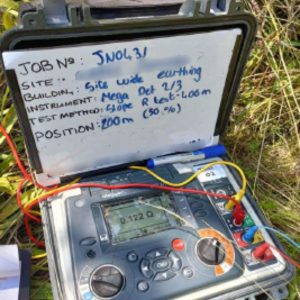

| Earth Resistance Testing | Verifying the site’s main earth resistance value using the Slope Method. |

| Fence Bonding Evaluation | Testing sample zones for compliance, accompanied by recommendations for a full perimeter inspection |

Site-Testing Results

The site’s main earthing system (MES) demonstrated a strong connection, with a measured resistance of 0.122 ohms (suitable for HV applications). However, our team uncovered several bonding failures across HV equipment, traywork, lighting systems, and perimeter fencing.

We found several continuity readings that exceeded acceptable limits (e.g., >2.5mΩ for HV gear, >10mΩ for general bonding), indicating degraded or insufficient connections. Visual inspections further supported these concerns. Our earthing coordinators noted physical defects such as disconnected fence braid links, corrosion at clamp terminals, and missing bonding conductors in several locations. These issues presented risks to site compliance and operational safety in the event of earth faults.

EPS Recommendations

Following our visit to the client’s energy recovery facility, we issued a detailed plan for remedial action. Our specialist earthing coordinators specified the exact locations and equipment within the site that required correction, including actions such as:

- Re-bonding non-compliant assets

- Applying protective coatings

- Scheduling a follow-up inspection cycle

Overall, we verified that the client’s interconnected HV/LV earthing system operates safely. This was demonstrated by its low earth resistance and satisfactory earth potential rise (EPR).

Conclusion

This project is a perfect example of how crucial periodic site-testing is for large energy facilities. By identifying failures and non-conformities early, we can establish a clear path to compliance and increased site safety. Our earthing condition assessments help to safeguard personnel, equipment and operational continuity, aligning the site to regulatory standards and best practices.

Earthing Systems Degrade Over Time. When was the Last Time You Tested Yours?

EPS offers a comprehensive suite of earthing and lightning protection testing services, including but not limited to:

- Annual & Periodic Testing

- Gap Analysis Reporting

- Soil Resistivity Testing

- Fall of Potential Testing

- Lightning Protection Inspections & Strike Risk Assessments.

Our earthing experts have 80+ years combined experience in delivering accurate, standards-aligned site audits backed by in-depth and actionable reporting.

📩 Get in touch today at earthing@engineeringpowersolutions.co.uk to schedule your assessment or request a quote.